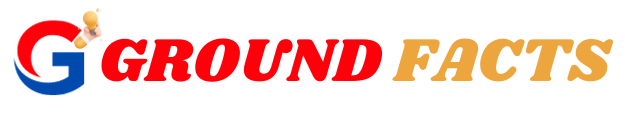

When it comes to material handling in industries like mining, construction, and agriculture, the right conveyor belt can make all the difference. One of the most effective solutions for transporting materials on inclines is the chevron conveyor belt. In this comprehensive guide, we will explore what makes this belt unique, its advantages, and why choosing reputable chevron conveyor belt suppliers is essential for efficiency and durability.

Introduction to Chevron Conveyor Belt

The chevron conveyor belt is a specially designed conveyor belt featuring a pattern of raised sections, or chevrons, on its surface. These chevrons help prevent material slippage during transportation on inclined or steep surfaces. Unlike flat belts, chevron belts are perfect for moving bulk materials such as coal, sand, gravel, minerals, and agricultural products over gradients of up to 40 degrees. Their unique structure makes them an indispensable choice in various industrial applications where stability and efficiency are critical.

Why Chevron Conveyor Belt is Different from Standard Belts

The main difference between a standard flat belt and a chevron belt lies in their functionality on inclined surfaces. Traditional belts are excellent for horizontal transportation but fail to maintain material stability on slopes. On the other hand, a chevron conveyor belt is designed with patterns that grip the material, reducing the risk of rollback. This feature ensures smooth and efficient transportation, saving time and reducing material wastage. Its adaptability across multiple industries further enhances its value in heavy-duty operations.

Applications of Chevron Conveyor Belts Across Industries

Certain industries rely heavily on chevron belts due to their unique design and performance capabilities. Here are some key sectors where these belts play a vital role:

- Mining Industry: For transporting coal, ore, and minerals on steep inclines.

- Agriculture: Moving grains, seeds, and fertilizers without spillage.

- Construction: Handling sand, gravel, and other bulk materials.

- Recycling Plants: For moving waste materials securely and efficiently.

The adaptability of chevron belts in different environments makes them a go-to solution for businesses seeking efficiency and reliability in bulk material handling.

Types of Chevron Conveyor Belts

Chevron belts come in different designs and specifications to meet the diverse needs of industries. Some common types include:

- Open V Type: Provides excellent grip and is suitable for steep inclines.

- Closed V Type: Offers continuous material movement with minimal spillage.

- Lug Type: Perfect for heavier loads and steeper gradients.

Choosing the right type of chevron belt depends on the nature of the material being transported and the degree of incline required. Each design is tailored to improve performance under specific operating conditions.

Key Advantages of Using Chevron Conveyor Belts

Using chevron belts offers numerous benefits to businesses, including:

- Improved Efficiency: Faster and safer transportation on inclines.

- Reduced Material Loss: The raised pattern minimizes slippage and spillage.

- Durability: Designed to withstand harsh industrial conditions.

- Cost-Effective: Lower maintenance costs due to reduced material loss and downtime.

These benefits highlight why companies in heavy industries prefer chevron belts for reliable and long-term solutions.

Why Choose Trusted Chevron Conveyor Belt Suppliers?

The role of experienced chevron conveyor belt suppliers cannot be overstated. Choosing the right supplier ensures:

- Quality Assurance: High-grade materials and compliance with industry standards.

- Customization: Tailored belt designs for specific applications.

- Technical Support: Expert guidance on installation and maintenance.

- Warranty & After-Sales Service: Reliable support for long-term performance.

A trustworthy supplier guarantees not just a product but a complete solution that enhances productivity and minimizes operational risks.

Maintenance Tips for Chevron Conveyor Belts

To ensure maximum lifespan and performance of your chevron belt, regular maintenance is key. Here are some tips:

- Inspect the belt regularly for wear and tear.

- Keep the belt clean to prevent buildup of material residues.

- Ensure proper alignment and tension during operation.

- Lubricate moving parts to reduce friction and wear.

Implementing these practices will help reduce downtime and maintain smooth operations in the long run.

Factors to Consider Before Buying a Chevron Conveyor Belt

Before purchasing a chevron belt, businesses should evaluate several factors:

- Material Type: Determine the nature of the material being transported.

- Incline Angle: Match the belt design with the slope requirements.

- Load Capacity: Ensure the belt can handle the desired load efficiently.

- Supplier Reputation: Choose reliable chevron conveyor belt suppliers to avoid quality issues.

Making an informed decision ensures higher efficiency and longer service life for your conveyor system.

FAQ: Chevron Conveyor Belt

What is the maximum incline for a chevron belt?

Chevron belts can handle inclines of up to 40 degrees, depending on the pattern and design.

Can chevron belts be customized?

Yes, most suppliers offer customization options to meet specific operational requirements.

How long does a chevron conveyor belt last?

With proper maintenance, these belts can last several years even in demanding environments.

Are chevron belts suitable for wet conditions?

Yes, their design provides excellent grip even in wet and slippery conditions.

Conclusion

In conclusion, the chevron conveyor belt is an essential component in industries that require reliable material handling on inclined surfaces. Its unique design, combined with durability and efficiency, makes it a top choice for various applications. Partnering with reputable chevron conveyor belt suppliers ensures you get a product that meets your operational needs while providing long-term value. By investing in quality belts and maintaining them properly, businesses can achieve higher productivity and lower operational costs.